Rupture Discs (Bursting Discs)

Rupture Discs (Bursting Discs) function as a pre-designed "weak point" in a pressurized system, and they should be the strongest part of your pressure protection system. Continental Disc Corp's rupture discs (bursting discs) utilize innovative and patented designs, the highest quality materials from traceable sources, and ISO 9001 manufacturing procedures performed by skilled craftsmen.

Why Choose a Rupture Disc??

Aside from instantaneous full relief, zero leakage and lower operating costs. Rupture discs (bursting discs) are a failsafe relief device and that is a significant advantage if the purpose of your relief device is protection of personal and equipment. Valves can stick, corrode, be damaged or miss assembled when serviced. All of which can result in a failure to relieve and result in a potentially catastrophic outcome. HPX rupture discs are a fail safe design which, regardless of damage, corrosion and age, will still burst at or below it's certified value.

Aside from instantaneous full relief, zero leakage and lower operating costs. Rupture discs (bursting discs) are a failsafe relief device and that is a significant advantage if the purpose of your relief device is protection of personal and equipment. Valves can stick, corrode, be damaged or miss assembled when serviced. All of which can result in a failure to relieve and result in a potentially catastrophic outcome. HPX rupture discs are a fail safe design which, regardless of damage, corrosion and age, will still burst at or below it's certified value.

Rupture Disc Advantages and Benefits

- Fail safe designs

- Instantaneous full relief

- Zero leakage

- Maximum relief capacity

- Quick change out

- No moving parts to wear, sieze, break or stick

- No routine servicing requirements

Products:

![]()

HPX® - Continental Rupture Discs

HPX® - Continental Rupture Discs

Rupture disc offered with a choice of 90% or true 95% operating to burst ratio.

The HPX® Rupture Disc (bursting disc) is a solid metal, scored, reverse acting rupture disc utalising CDC's industry leading technology and craftsmanship. The HPX® Rupture Disc is a high precision reverse acting rupture disc that offers proven performance in excess of 5 million full cycles at 95% operating ratio. Thats over 5 times longer than our nearest competitor!

The HPX® Rupture Disc excels in fully liquid, gaseous and partial gas/liquid systems. Full opening guaranteed.

Features include:

- Zero Leakage

- Certified 95% operating to burst ratio ASME XIII (100% under ISO 4126-2)

- 5 million+ cycle life

- Industry leading Kr (flow resistance) values for gas and liquid. Certified under ASME.

- Superior seal design removes need for pre-torque holder & torque sensitivity of discs and is drastically more durable than traditional bite seals that wear out or get crushed under unever or over torqued bolts

- Non-fragmenting

- Fail-safe 1:1 design for the ultimate level of operator and machine safety

- Compliance with AS1358, ASME XIII, PED, ISO, NACE, CE, NADCAP, Reach and more.

- SIL 4 - Independantly evaluated to IEC 61508 for a safety level of 4

![]()

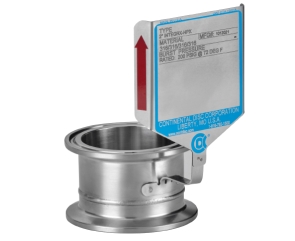

APX® - Continental Rupture Discs

APX® - Continental Rupture Discs

Rupture disc offered with a choice of 90% or true 95% operating to burst ratio.

The Continental Disc APX™ rupture disc is a semicircular scored reverse acting rupture disc that is ideal for liquid or gas/vapor applications. In terms of performance, precision, and durability, the APX rupture disc outperforms the competition. One of several benefits of the APX is the flexibility to tailor it to the demands of the customer, particularly regarding flexibility in holder materials of construction.

The APX® Rupture Disc excels in fully liquid, gaseous and partial gas/liquid systems. Full opening guaranteed.

Features include:

- Zero Leakage

- Certified 95% operating to burst ratio ASME XIII (100% under ISO 4126-2)

- Superior seal design removes need for pre-torque holder & torque sensitivity of discs and is drastically more durable than traditional bite seals that wear out or get crushed under unever or over torqued bolts

- Non-fragmenting

- Fail-safe 1:1 design for the ultimate level of operator and machine safety

- Compliance with AS1358, ASME XIII, PED, ISO, NACE, CE, NADCAP, Reach and more.

- Holder Materials: Duplex, Super Duplex, Super Austenitic, 304/304L SS, Alloy C22, Alloy 625, Titanium, and other materials upon request

![]()

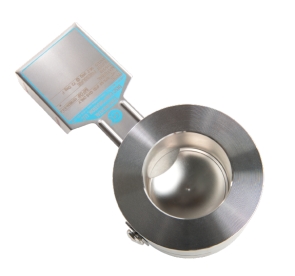

SANITRX® HPX - Continental Rupture Discs

SANITRX® HPX - Continental Rupture Discs

Sanitary Rupture disc with HPX's class leading performance

The SANITRX HPX® rupture disc (bursting disc) is a scored reverse acting rupture disc (bursting disc) designed specifically for the pharmaceutical, food and beverage, and biotech industries. This differential pressure relief device features an instantaneous full-open relief area for protecting equipment, vessels, systems and people from an overpressure condition. This high precision reverse acting rupture disc (bursting disc) offers proven performance in excess of 5 Million cycles at a 95% operating ratio.

SANITRX HPX® Rupture Discs comply with essential criteria of ASME BPE and USP Class VI and is independantly evaluated to SIL 4, IEC 61508.

![]() SANITRX HPX Data Sheet

SANITRX HPX Data Sheet ![]() 3/4" SANITRX Data Sheet

3/4" SANITRX Data Sheet

![]() Sanitary Accessories

Sanitary Accessories

![]()

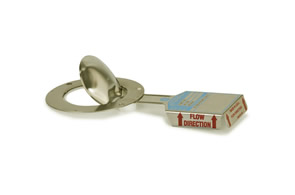

INTEGRX® HPX - Continental Rupture Discs

INTEGRX® HPX - Continental Rupture Discs

Welded Sanitary Rupture disc with HPX's class leading performance

The Continental Disc IntegrX-HPX™ rupture disc addresses the need to improve process performance, reliability, and safety in biopharmaceutical, food and beverage, and sanitary applications.

- Crevice free design per ASME BPE-2019

- Standard wetted surface finish meets 20 Ra microinch (0.5 micrometer)

- CIP and SIP cleanable to ASME BPE requirements

- Ideal for liquid or gas/vapor applications

- Rupture disc can be operated to full vacuum

INTEGRX HPX® Rupture Discs comply with essential criteria of ASME BPE and USP Class VI

![]()

SRA - Continental Rupture Discs

SRA - Continental Rupture Discs

Compact reverse acting rupture disc in a threaded Rupture Discs Assembly

The Screw-Type assembly is a reusable disc holder for systems pressurized up to 15,000 psig, and the Tite-Seal is a sealed, disposable unit for systems under 3,000 psig. Both are designed for miniature applications like A/C and refrigeration units, gas cylinders and portable compressed-air systems.

The Tite-Seal assembly features a rupture disc sealed between brass fittings. After relieving an overpressure condition, change-out is easily performed by replacing the entire assembly.

![]() Tite-Seal/Screw Type Data Sheet

Tite-Seal/Screw Type Data Sheet![]()

HPX-Ta (Tantalum) - Continental Rupture Discs

HPX-Ta (Tantalum) - Continental Rupture Discs

Rupture Disc constructed of Tantalum for superior corrosion resistance

The HPX-Ta™ Rupture Disc (bursting disc) is a Tantalum semicircular scored reverse acting rupture disc designed specifically for use in highly corrosive media, such as bromine, chlorine, HCL, nitric acid or sulfuric acid. In certain concentrations, temperatures and moisture conditions, Tantalum is frequently the only suitable rupture disc material for the application.

![]()

LOTRX® - Continental Rupture Discs

LOTRX® - Continental Rupture Discs

Reverse Acting Rupture Disc / Burst Disc for very low pressures

The LOTRX® Rupture Disc (bursting disc) is a scored reverse acting rupture disc (bursting disc) that utilizes failure initiating indents, a highly accurate manufacturing method to achieve and control a burst pressure at close tolerances, plus a precision semicircular score to provide a clean, consistent opening pattern. The LOTRX® Rupture Disc (bursting disc) is designed for extremely low pressure applications below the range of the HPX® Rupture Disc product family.

Burst pressure as low as of 0.1 bar

![]()

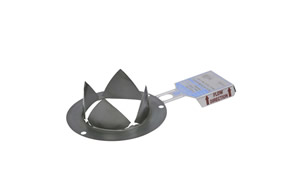

RCS - Continental Rupture Discs

RCS - Continental Rupture Discs

Reverse acting rupture disc up to 800mm for Gas & Vapour Service

The RCS Rupture Disc (bursting disc)is a reverse acting, cross-scored, solid metal rupture disc (bursting disc), providing reliable pressure relief protection, easy installation, and retrofit to your pre-existing piping arrangement. Available in sizes outside the range of the HPX® Rupture Disc product family.

![]()

SANITRX® LPX - Continental Rupture Discs

SANITRX® LPX - Continental Rupture Discs

Low Pressure Sanitary Rupture Disc

The SANITRX® LPX is a stainless steel, reverse acting rupture disc (bursting disc) designed specifically for the pharmaceutical, food and beverage, and biotech industries.

This differential pressure relief device features an

instantaneous full-open relief area for protecting

equipment, vessels, systems and people from an

overpressure condition.

![]() SANITRX LPX Data Sheet

SANITRX LPX Data Sheet

(back to top)

![]()

SANITRX® HPX II - Continental Rupture Discs

SANITRX® HPX II - Continental Rupture Discs

Sanitary rupture disc for higher pressure applications

The SANITRX HPX® II Rupture Disc is a semicircular, scored, reverse acting rupture disc (bursting disc) designed specifically for applications in the pharmaceutical, food & beverage and biotech industries that require pressures above our SANITRX HPX® Rupture Disc. Available in sizes 1 ½” to 4,” this rupture disc is available to fit between standard sanitary ferrules, NA CONNECT® flanges or SANITRX® fittings. SANITRX HPX® II rupture discs are shipped in sanitary, environmentally friendly, non-toxic packaging.

![]()

Tech Review

Reverse Acting (Reverse buckling) Rupture Discs

First choice for pulsating and cyclic pressures.

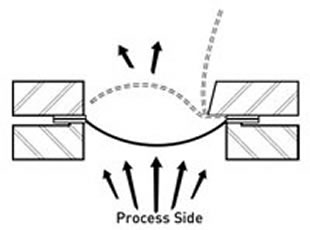

Reverse Acting Rupture Discs (bursting discs) are oriented

in a system with

the

process media pressure

against the convex side of the disc,

placing the

rupture disc (bursting disc) in compression. As the

burst pressure rating of the

disc is reached,

the compression loading on the rupture disc

causes it to reverse,

snapping through

the

neutral position and causing it to open by a

predetermined

scoring pattern.

A reverse acting rupture disc provides advantages,

as compared to tension type

rupture discs, which

may warrant consideration when selecting a

rupture disc.

These advantages include:

- Available with maximum recommended

operating pressure ratios up to

95% of the stamped burst pressure. - Up to full vacuum capabilities without the need

of an additional support

member. - Longer service life under cyclic or pulsating conditions.

- Constructed using thicker materials providing greater resistance to corrosion

Forward Acting (Tension Loaded) Rupture Discs

Economical option suited to static conditions.

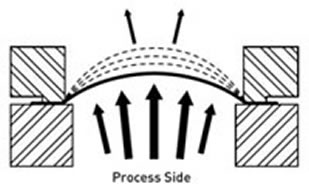

Tension Type Rupture Discs (Bursting discs) are oriented in a

system with the

process media

pressure against

the concave side of the rupture disc. As the

process

pressure increases beyond the allowable operating

pressure, the

rupture

disc starts to grow. This

growth will continue as the pressure increases,

until the tensile strength of the material is reached

and rupture occurs.

Useful links: Forward acting rupture discs, Specialised Rupture Disc Holder Products, Specialised Rupture Discs, Burst indicators

![]()

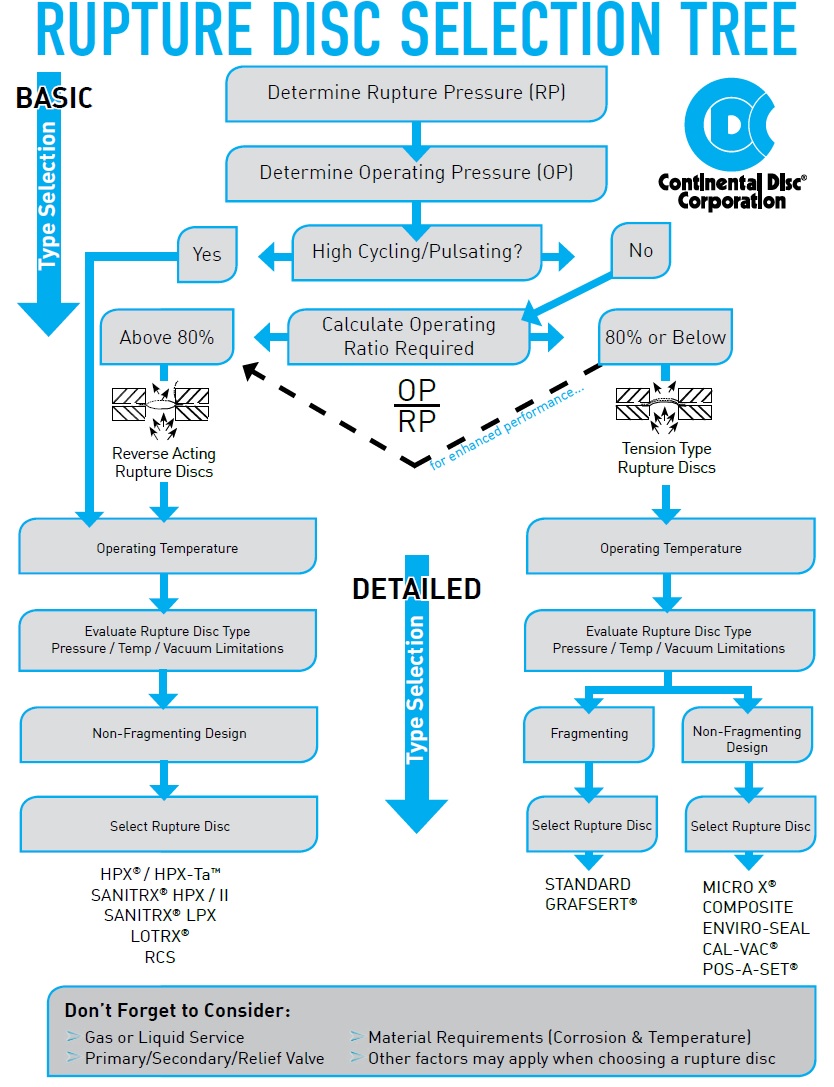

Rupture Disc Selection Guide

![]()

Continental Disc Corporation

Continental Disc Corporation manufactures rupture

discs (bursting discs) to our customers’ specifications which protect

vessels, equipment and systems against damaging

overpressure conditions.

QUALITY

Quality begins during our first contact with you. That quality is an

integral part of every step we take to provide you with what you expect

to receive. All manufacturing is performed under an approved ISO

9001 Quality Assurance System. Continental Disc Corporation can

supply rupture discs (bursting discs) certified to the standards of ASME, the European

Pressure Equipment Directive, 3A Sanitary Standards Council and

many others.

SERVICE

A commitment to supply the services you expect:

- Technical assistance, training and support

- Fast, technical, easily understood quotations

- Providing product to your specifications

- Shipping schedules that are unmatched in the industry

Continental Disc Corporation offers an emergency service program to meet your needs. Shipping schedules are adjusted daily to meet your emergency requirements.

![]()

Solutions...for Tough Pressure Relief Problems

Whether it’s from the standard product line, or a custom-manufactured rupture disc (bursting disc) for a one-of-a-kind application, Continental Disc Corporation has built a reputation for solving the toughest pressure relief problems for OEM’s...Defense...Space Exploration...Aircraft and Aerospace...Chemical and Petrochemical... Food Processing...Electronics..and countless more.

![]()

Problem Solving

Continental Disc Corporation’s custom manufacturing capabilities have been tapped for such wide-ranging projects as air conditioning units, oxygen supply systems, aircraft ejection seats, sonobouys and the space shuttle.

The same engineering, testing and manufacturing talent that has solved one-of-a-kind problems for worldwide industries is now available to deliver innovative solutions for your specific pressure relief problems.

![]()

Working With Specialized Technologies...Like Yours

Solving pressure relief problems for you is the special role played by Continental Disc Corporation’s Product

Development Group and the Special Products Group. This pool of product development expertise has been

retrofitting Continental Disc Corporation products into clients’ systems for nearly 50 years. They are engineers

who are at home with special or exotic materials, ultrahigh or ultralow burst pressures, as well as state-of-the-

art processing and testing requirements.

Whether your needs are for quantities of one or one hundred thousand, Continental Disc is ready to solve your pressure relief problems.