Diaphragm Seals (Chemical Seals)

Diaphragm seals, also referred to as a chemical seals. are used to isolate the primary pressure instrument from a range of process conditions that include corrosion, contaminants, temperature, pressure spikes, vibration and product build up.

A diaphragm seal comprises a sealed chamber and a flexible membrane that allows the process pressure to be transmitter hydraulically, via a non compressible fluid, to the primary pressure element. The primary element could be a pressure switch, pressure transmitter or pressure gauge.

Diaphragm seals could also be used to locate the pressure instrument in a more convenient location for operators without the need of long impulse lines that can become blocked or become a source of error.

Useful links: Pressure Transmitters, Differential Pressure Transmitters.

![]()

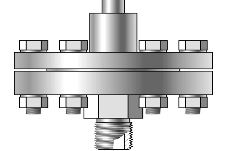

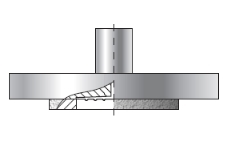

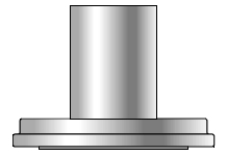

S-Comp - General Purpose Bolted Diaphragm Seal

S-Comp - General Purpose Bolted Diaphragm Seal

This design uses a large diaphragm for higher accuracy and greater thermal stability. The larger surface area of the diaphragm seal enables it to work effectively at the ranges as low as 0.1 bar.

- Standard material of construction: 316LSS

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 16 bar

- Temps up to 390 deg C

![]()

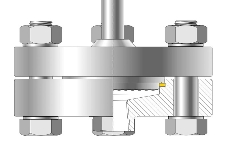

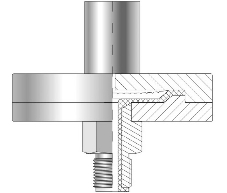

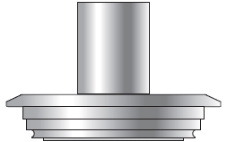

S-Comp 10M - Medium to High Pressure Diaphragm Seal for up to 100 bar

S-Comp 10M - Medium to High Pressure Diaphragm Seal for up to 100 bar

Medium pressure diaphragm seal for pressures up to 100 bar with a 70 mm diameter diaphragm for high accuracy and greater thermal stability.

- Standard material of construction: 316LSS

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 100 bar

- Temps up to 390 deg C

![]()

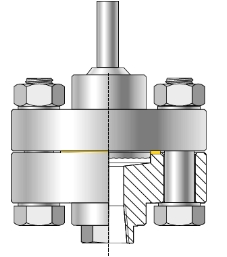

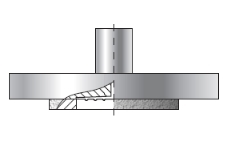

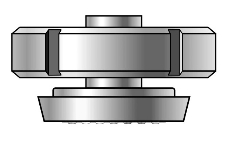

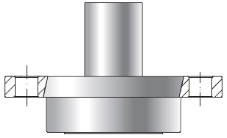

S-Comp 25 / 60M - High Pressure Diaphragm Seal for up to 600 bar

S-Comp 25 / 60M - High Pressure Diaphragm Seal for up to 600 bar

High pressure diaphragm seal for pressures up to 600 bar with a 70 mm diameter diaphragm for high accuracy and greater thermal stability.

- Standard material of construction: 316LSS

- Maximum working pressure S-Comp25: 250 bar

- Maximum working pressure S-Comp60: 600 bar

- Temps up to 390 deg C

![]()

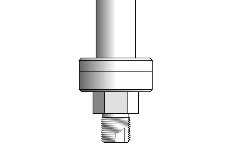

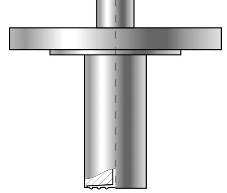

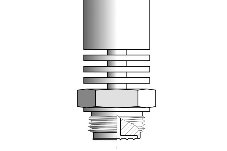

S-Mazut - Compact General Purpose Diaphragm Seal

S-Mazut - Compact General Purpose Diaphragm Seal

This threaded diaphragm seal is an ideal choice for isolating instruments from temperature, corrosives, thick mediums or to shield against pressure spikes and pulsation.

- Standard material of construction: 316LSS

- Minimum recommended span: 0.05 bar

- Maximum working pressure: up to 110 bar

- Remote option configurable for up to 390 deg C

![]()

S-P - General Purpose Flush Faced and Flanged diaphragm Seal

S-P - General Purpose Flush Faced and Flanged diaphragm Seal

A flush faced diaphragm seal providing excellent resistant to coating mediums. It's designed to mount directly to customer flanges in axial or radial formats. The large diaphragm also enables measurement spans as low as 0.025 bar and

- Standard material of construction: 316LSS

- Minimum recommended span: 0.025 bar

- Maximum working pressure: 40 bar

- Temps up to 390 deg C

![]()

S-CompCh - Teflon lined Diaphragm Seal for Aggressive Mediums

S-CompCh - Teflon lined Diaphragm Seal for Aggressive Mediums

The S-Ch diaphragm seal utalises a Tantalum diaphragm and a thick Teflon liner that covers all other internal components including the sealing face of the thread or flange for the highest level of corrosion protection, durability and minimal potential for leakage.

- Cost effective

- Threaded or Flanged process connection

- Wetted parts: Teflon and Tantalum

- Minimum recommended span: 0.4 bar

- Maximum working pressure: 16 bar

![]()

S-Ch - Flush Faced Diaphragm Seal for aggressive mediums

S-Ch - Flush Faced Diaphragm Seal for aggressive mediums

A flush faced diaphragm seal ideally suited for corrosive and thick mediums that would clog regular diaphragm seal assemblies. Designed to mount directly customer flanges in axial or radial format.

- Wetted parts: Gold, Hastelloy C276, Monel, Nickel, Tantalum, Teflon or Titanium

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 40 bar

![]()

S-T - Extended Flush Faced Diaphragm Seal

S-T - Extended Flush Faced Diaphragm Seal

The S-T diaphragm seal is designed to extend through nozzles to meet the inside wall of a vessel or pipe. This ensures there's is no dead space for media to accumulate and clog the measurement.

- Nozzle length made to order

- Standard material of construction: 316LSS

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 16 bar

![]()

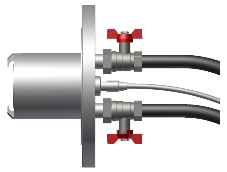

ST-K-P - Self Cleaning Diaphragm Seal

ST-K-P - Self Cleaning Diaphragm Seal

The ST-K-P diaphragm seal has diaphragm cleaning jets angled across the flush face to provide a means to clean the diaphragm seal without ever having to remove it from the process. Being able to clean while in situ is a great way to reduce maintenance costs and increase uptime.

- Standard material of construction: 316LSS

- DN100 mm flange

![]()

S-Clamp - Sanitary Diaphragm Seal with Tri-Clamp (Tri-Clover) Connection

S-Clamp - Sanitary Diaphragm Seal with Tri-Clamp (Tri-Clover) Connection

Sanitary tri-clamp (tri-clover) diaphragm seal with a standard finish of <0.2 um Ra, completed in 316SSL and available in a choice of hygienic fills to suit pharmaceutical, food and beverage, bio tech and other applications requiring the highest degree of sanitation.

- Standard finish of <0.2 µm Ra

- Food grade fills available

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 25 bar

![]()

S-Pozium - Universal Process Connection type Sanitary Diaphragm Seal

S-Pozium - Universal Process Connection type Sanitary Diaphragm Seal

The S-Pozium is a sanitary diaphragm seal designed for flush mounting with no room for material to accumulate or washing agents to get trapped when cleaning. The S-Pozium Sanitary Diaphragm seal also offers excellent thermal stability properties compared with other designs.

- Standard finish of <0.2 µm Ra

- Food grade fills available

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 25 bar

![]()

S-DIN - Sanitary Diaphragm Seal for DIN 11851 connections

S-DIN - Sanitary Diaphragm Seal for DIN 11851 connections

The S-DIN sanitary diaphragm seal per DIN 11851 is a hygienic union design that permits flush alignment with the inside of process vessels and lines so there is no place for material or washing agents to accumulate.

- Standard finish of <0.2 µm Ra

- Food grade fills available

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 25 bar

![]()

S-SMS - SMS type Sanitary Diaphragm Seal

S-SMS - SMS type Sanitary Diaphragm Seal

The S-SMS sanitary diaphragm seal is a hygienic union design for hygienic service in diary, food and beverage and other sanitary applications.

- Standard finish of <0.2 µm Ra

- Food grade fills available

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 25 bar

![]()

S-Varivent - Varivent Compatible Sanitary Diaphragm Seal

S-Varivent - Varivent Compatible Sanitary Diaphragm Seal

The S-Varivent sanitary diaphragm seal is compatible with Varivent connections to allow easy dismantling and cleaning in sanitary and hygienic applications.

- Standard finish of <0.2 µm Ra

- Food grade fills available

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 25 bar

![]()

S-DRD - DRD Flange Compatible Sanitary Diaphragm Seal

S-DRD - DRD Flange Compatible Sanitary Diaphragm Seal

The S-DRD sanitary diaphragm seal is a flanged design for easy dismantling and cleaning in sanitary and hygienic applications.

- Standard finish of <0.2 µm Ra

- Food grade fills available

- Minimum recommended span: 0.1 bar

- Maximum working pressure: 25 bar

![]()

S-RC

- High Temperature Diaphragm Seal

S-RC

- High Temperature Diaphragm Seal

A high temperature diaphragm seal for integral mounted applications up to 260 deg C. The radiator fins and special fill of the S-RC provides efficient cooling of the internal fluid to enable accurate and reliable measurements of hot process mediums.

- Standard material of construction: 316LSS

- Minimum recommended span: 0.4 bar

- Maximum working pressure: 100 / 250 bar

- Operating temps to 260 deg C (390 deg C in remote format)