Magnetic Flow Meters -

Electromagnetic Flow Meters

Magnetic Flow Meters -

Electromagnetic Flow Meters

Magnetic Flow Meters, often called Magflow Meters or magmeters for short, and more formally known as Electromagnetic Flow Meters, measure flow based on the potential difference generated by the fluid's movement within the instrument’s metering tube. This method is highly accurate and reliable, even under fluctuating process conditions, making the Magnetic Flow Meter an ideal solution for most applications where the fluid has sufficient conductivity.

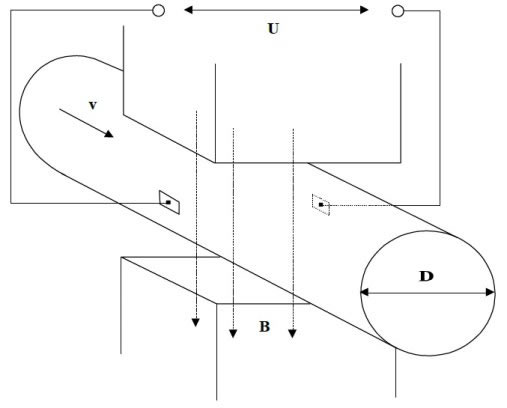

Principle of Operation:

The Magnetic Flow Meter operates on the principle of electromagnetic induction. According to Faraday’s law, when a conductor moves through a magnetic field, an electrical voltage is induced. The induced voltage is calculated using the following equation:

U = B x D x v

U – induced voltage

v – the average flow velocity vector

D – diameter of the pipe

B – magnetic flux density

When the magnetic flux density (B) and pipe diameter (D) remain constant, the induced voltage is directly proportional to the average flow velocity. The fluid flows perpendicularly through the flowmeter's magnetic field. The induced electrical voltage is detected by two electrodes positioned at right angles to both the magnetic field and the flow direction. This voltage is generated as the electrically conductive fluid passes through. A rectangular-wave current is generated by the converter, which then powers the spool coils of the measuring sensor, creating the flowmeter’s magnetic field. The power supply ensures continuous excitation of the coils, maintaining stable operation of the flowmeter under all working conditions.

![]()

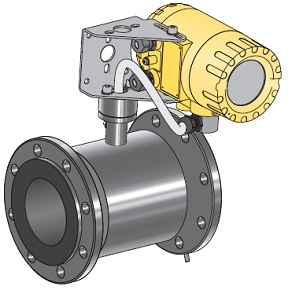

PEM-1000ALW - Electromagnetic Flow Meter

PEM-1000ALW - Electromagnetic Flow Meter

Integral magnetic flow meter

Multipurpose Electro Magnetic flow meter for liquids and slurries with an integral Electronics. The PEM-1000ALW is suitable for any medium with a conductivity ≥ 5 uS/cm making it extremely flexible and compatible with wide range of applications.

On-board features for dosing, bi-directional totalising, empty/partial fill alarms, diagnostics, zero flow detection, and more.

Options for:

- Mounting without straight sections

- High viscosity mediums

- High temperatures

- Enhanced accuracy

- Sanitary approval

- Liquids

- Slurries

- Corrosive Chemicals

- Paints and Pastes

- Sanitary and Potable Water

- Water and Wastewater

Sizes: 10 mm to 1000 mm (1/2" to 40" ANSI)

Suitable for:

![]()

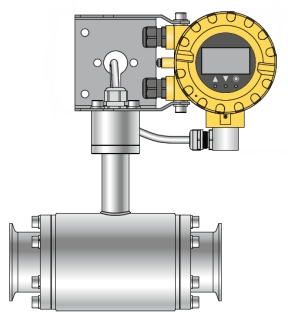

PEM-1000NW - Electromagnetic Flow Meter

PEM-1000NW - Electromagnetic Flow Meter

Magnetic flow meter with remote sensor

Multipurpose Electro Magnetic flow meter for liquids and slurries with a remote electronics. The PEM-1000NW is suitable for any medium with a conductivity ≥ 5 uS/cm.

On-board features for dosing, bi-directional totalising, empty/partial fill alarms, zero flow detection, diagnostics, and more.

Options for:

- Mounting without straight sections

- High viscosity mediums

- High temperatures

- Full submersion of the sensor

- Enhanced accuracy

- Sanitary approval

- Liquids

- Slurries

- Corrosive Chemicals

- Paints and Pastes

- Sanitary and Potable Water

- Water and Wastewater

Sizes: 10 mm to 1000 mm (1/2" to 40" ANSI)

Suitable for:

![]()

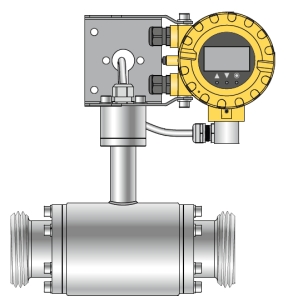

PEM-500 - Electromagnetic Flow Meter

PEM-500 - Electromagnetic Flow Meter

Compact and integral electro magnetic flow meter

Multipurpose Electro Magnetic flow meter for liquids and slurries with an integral Electronics. The PEM-500 is suitable for any medium with a conductivity ≥ 5 uS/cm.

On-board features for dosing, bi-directional totalising, empty/partial fill alarms and more.

Options for:

- Mounting without straight sections

- High viscosity mediums

- High temperatures

- Enhanced accuracy

- Sanitary approval

Sizes: 10 mm to 300 mm (1/2" to 12" ANSI)

- Liquids

- Slurries

- Corrosive Chemicals

- Paints and Pastes

- Sanitary and Potable Water

- Water and Waste Water

Suitable for:

![]()

PEM-1000ALW Tri-Clamp - Sanitary Electromagnetic Flow Meter

Sanitary magnetic flow meter - Integral and remote

Multipurpose Electro Magnetic flow meter for sanitary liquids and slurries with a sanitary Tri-clover (Tri-clamp) connection. The PEM-1000ALW is suitable for any medium with a conductivity ≥ 5 uS/cm.

On-board features for dosing, bi-directional totalising, empty/partial fill alarms and more. Suitable for CIP & SIP processes

Sizes: 25 mm to 100 mm (1" to 4")

Suitable for:

- Pharmaceuticals

- Sanitary applications

- Potable water

- Biotech

- Food and Beverages

![]()

PEM-1000ALW DIN-11851 - Sanitary Electromagnetic Flow Meter

PEM-1000ALW DIN-11851 - Sanitary Electromagnetic Flow Meter

Sanitary magnetic flow meter - Integral and remote

Multipurpose Electro Magnetic flow meter for sanitary liquids and slurries with a sanitary DIN-11851 connection. The PEM-1000ALW is suitable for any medium with a conductivity ≥ 5 uS/cm.

On-board features for dosing, bi-directional totalising, empty/partial fill alarms and more. Suitable for CIP & SIP processes

Sizes: 25 mm to 100 mm (1" to 4")

Suitable for:

- Pharmaceuticals

- Sanitary applications

- Potable water

- Biotech

- Food and Beverages

![]()

Aplisens Flow Lab - ISO/IEC 17025:2018-02 accreditation

Measurements are conducted on a fully automated test station that uses water as the flowing medium, with precise control of pressure and temperature. To determine the measurement errors of the tested flowmeters, either the weighing or volumetric method is applied, using both moving and static start/stop techniques. The volumetric method utilizes reference flowmeters, while the weighing method employs 600 kg and 12,000 kg scales.

The Flow Laboratory calibrates electromagnetic flowmeters with diameters ranging from DN10 to DN350, covering flow rates from 0.4 to 1600 m³/h, in accordance with its accreditation scope.

Within the station’s operational range—flow rates from 0.05 to 1600 m³/h—Aplisens-manufactured electromagnetic flowmeters are calibrated, and flowmeters from other manufacturers can also be tested. Upon consultation with an Aplisens representative, it is possible during recalibration to verify the readings of both electronic and mechanical flowmeters and water meters, including those produced by other manufacturers.